|

Last week we discussed the fun topic of planning for our future success. This week is a bit of a bummer since we're focusing on failure.

We've identified three areas that can cause failure here at the shop: quality, production, and materials. Each of these areas have their own challenges but when they come together they can really cause chaos when trying to meet a shipping deadline. Quality - Our first line of defense against shipping poor quality products is our production assemblers. We train all our production assemblers to be their own quality assurance managers. They check every wire after it has been crimped, they check every heat shrink after it has been shrunk, and they visually inspect the wiring on every plug. As assemblies make their way through the production floor, they have various sets of eyes on them, making sure quality standards are kept. Assemblies finally make their way to our inspection department where they are tested, measured, poked, and prodded to make sure they are exactly what our customers are expecting. A failure at any stage of the process could mean shipping an inferior product to a customer. We have a saying at the shop, "It's ok to make a mistake but it's never ok to ship a mistake." Production - We believe in giving production assemblers everything they need to be successful at what they do. That includes lots and lots of training. When an inexperienced production assembler is set to work on an assembly without the proper training, that could spell disaster and cost us time and money in reworks. We write all our assembly instructions in-house and when it's time to build something new, we have someone from our engineering team sit with production assemblers and work with them to make sure the process runs smoothly. Materials - As soon as a purchase order has been confirmed, it heads over to our inventory department to start the process of assembling the production kit. The inventory specialists work with our purchasing department to make sure that materials are ordered in a timely manner, reducing the amount of time a kit sits on the shelf waiting for parts to arrive. Once materials have been assembled, the kit gets sent to our production department for assembly. The wrong materials or materials not ordered promptly could create havoc and lead to a failure in getting the order out in time. Even though we work really hard in trying to make sure that we follow our processes closely, we're also human, and sometimes we fail. Failure is a part of any business. Some businesses learn from their mistakes, correct themselves, and move forward. Unfortunately, other business don't. They fail and keep failing and it ends up costing them dearly. At Bridgeview, we accept failure as a normal part of life. What we don't accept is staying down. We get back up, dust ourselves off, and make sure we understand the lesson that failure enabled us to learn. Staying down and quitting is not an option. How have you dealt with failure? How have you learned and grown from it? Below: Haley (left) checks to make sure the packaging on an assembly is correct before bagging it. Ashlee (right) puts inventory away, making sure the parts go in the right bins.

0 Comments

Do you have a Plan B? Arnold Schwarzenegger has a popular motivational talk on YouTube discussing his dislike of Plan Bs.

You can find a short clip of the video below: www.youtube.com/watch?v=uGHI58Fhrgk Schwarzenegger's theory is that if you have a Plan B, you spend time and energy developing that plan when you could have spent time and energy working on Plan A. Considering his success, we think he's right. While it's absolutely normal to consider what you would do if your initial plans fail, your attention should be focused on success, not failure. We all fail and we all know that in order to be successful you have to learn from your failures and keep trying. But how many of us are actually planning for success? How many of us have thought about extra staffing requirements, additional office/shop space, increased purchasing, or more sales trips? Success means achieving your goals and while it's very important identify those goals, it's probably even more important to identify how those goals are going to be met. At Bridgeview, we value winning. We encourage a culture of success by rewarding the positive attitudes and behaviors of our team members. We root for our customers, empowering them to win in their chosen industries. Yes, we sometimes fail but those failures never keep us down for long. We learn, we get back up, and we prime ourselves for success next time. How are you planning for success? Below: Chris (left) is our latest new hire. By giving new people the support they need to learn, we're building up a strong team that can handle future success. Ben and Kevin (right) are working together to inspect assemblies. Making sure we build excellent products helps us to maintain our high standards as our company grows. Quality control is everyone's job. When it comes to inspecting work and looking for mistakes, we need to have a "self-employed" attitude. We are all the CEO of our own time and work. At Bridgeview, we encourage our team members to imagine themselves as owning their own companies and those companies contract with Bridgeview to provide labor. How would they feel about the quality of work their companies are providing to ours?

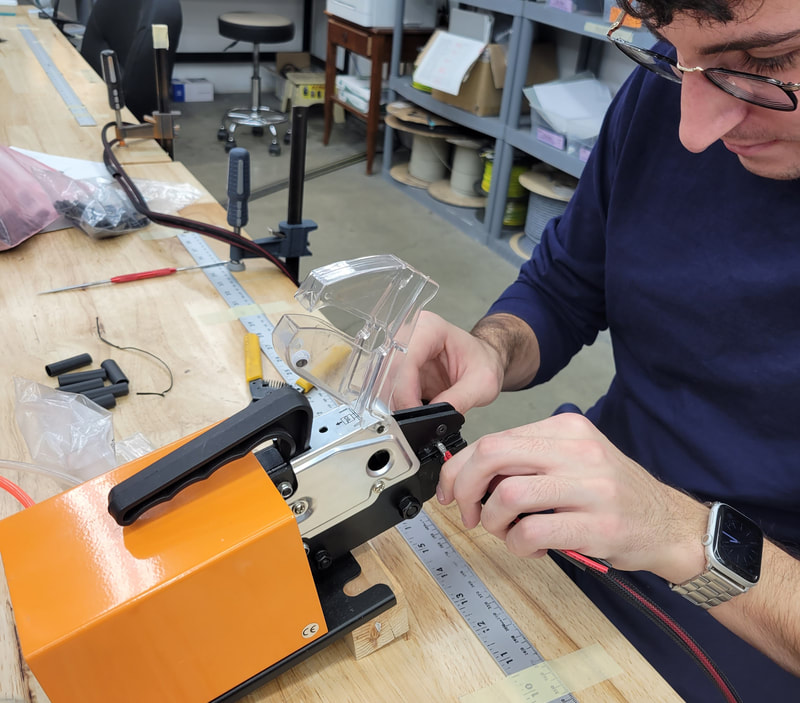

This attitude of being your own CEO doesn't just stop at quality. If the shop needs to be swept, someone will happily sweep it because they see the shop as theirs. If a team member needs help, someone will readily jump in because they want to see everyone here succeed. We are all interested in learning about our customers because it gives our work meaning to know who we're helping and what we're building. Even though there is a leadership team at Bridgeview, we try as much as possible to make decisions together with our team members so that they also feel ownership of the company. Even though we encourage them to see themselves as their own CEOs, they also understand the value of teamwork and company loyalty. No one can do this alone. Do you see yourself as your own CEO? How can you help your team see themselves in that way, too? Below: Peter (left) uses our pneumatic crimper and then inspects every crimp afterwards. Kevin (right) measures the location of the heat shrink carefully before applying it to heat. Everyone needs goals. Sometimes those goals are life changing, like saving for an early retirement, and sometimes those goals are more immediate, like making sure you drink 64 oz of water a day. We love setting goals and we encourage all of our team members to set goals as well.

One of the ways we help team members set and meet goals is by using internal reports. These reports give team members the data needed to see if they are moving towards their goals. One of our team members really wants to get better at soldering. He wants to get so good that eventually he'll be able to teach soldering to the public at the local maker space. He uses the data on our internal reports to see how fast he solders and how accurate his soldering is. He then sets goals based on those reports to see if he can get better. When he does see improvement, we celebrate his success with him and encourage him to continue his progress. Even personal goals, like getting out of debt, become opportunities to coach our team members. We all have experiences we can share and when we learn from each other, we become a stronger team. How do you encourage goal setting in your team? Below: Haley, Ashlee, and Peter (left) celebrate meeting our latest shipping goal. Collin (right) is currently going to school and has a goal of graduating with a mechanical engineering degree. |

AuthorsChristina and Kevin Hayward Archives

July 2024

Categories |

RSS Feed

RSS Feed